Comprehensive tank maintenance

Cleaning, full range of technical diagnostics, repair and maintenance works

Request a quote for comprehensive tank maintenance

Steps of comprehensive tank maintenance

NNIAT patented technologies ensure the return of up to 97% of oil organic part into the production cycle.

Specialists performing repair works have all necessary licenses and certificates.

Performed by advanced compounds, with subsequent quality control

New tanks erection and tanks reconstruction or modernization

Company Overview

Nizhny Novgorod Institute of Applied Technologies (NNIAT LLC) is the largest oilfield services company in Russia in the field of development and application of innovative technologies to solve the environmental problems of the industry.

The top priority of our activity is the implementation of the highest environmental standards, as well as the use of effective technologies aimed at preserving the environment and optimizing economic activity.

Today NNIAT LLC is a wide network of branches and representative offices in various cities of Russia, in the countries of near and far abroad.

We are proud to have proven ourselves to be a reliable partner for Oil and Gas companies, and to have gained vast experience over many years of cooperation with the industry leaders.

Benefits of our technology

No damage to the integrity of the tank steel structures

No pipeline wear

Saving time for washing out and removal of the main volume of solid oily wastes by 10 times

Full return of the liquefied oil product into production

Minimizing the sediment to be disposed

Eliminating the need for personnel presence inside the tank

Explosion proof washing out system and technology as a whole

Possibility of work execution during winter time

Minimum adverse environmental impact

Saving of steam for tank walls steaming

Complete neutralization of pyrophoric compounds in the tank

Our experience

We have been executing challenging tank cleaning projects since 2008.

Tanks of all types and sizes at oil refineries, pumping stations, product and raw material bases, oil terminals, power plants and boiler houses, including damaged and emergency tanks, as well as tanks with damaged bottom, with flooded and dropped to the bottom pontoons.

Order comprehensive tank maintenance

Guaranteed safety at the facility

Works at the facility are performed in compliance with safety requirements established by the Russian Federation laws, international standards, as well as safety requirements of the Client.

NNIAT LLC is licensed by RosTechNadzor (RTN) for the operation of industrial facilities with explosion, fire and chemical hazards of I, II and III class. Occupational health and Industrial safety Management system is in compliance with OHSAS 18001 requirements.

The personnel is duly qualified and certified, undergoes all the necessary types of trainings, briefings, internships and knowledge assessments. The personnel is fully equipped with personal and collective protective equipment, undergoes preliminary and regular medical examination.

Tank cleaning is carried out under a patented technology that minimizes the risks of incidents and accidents.

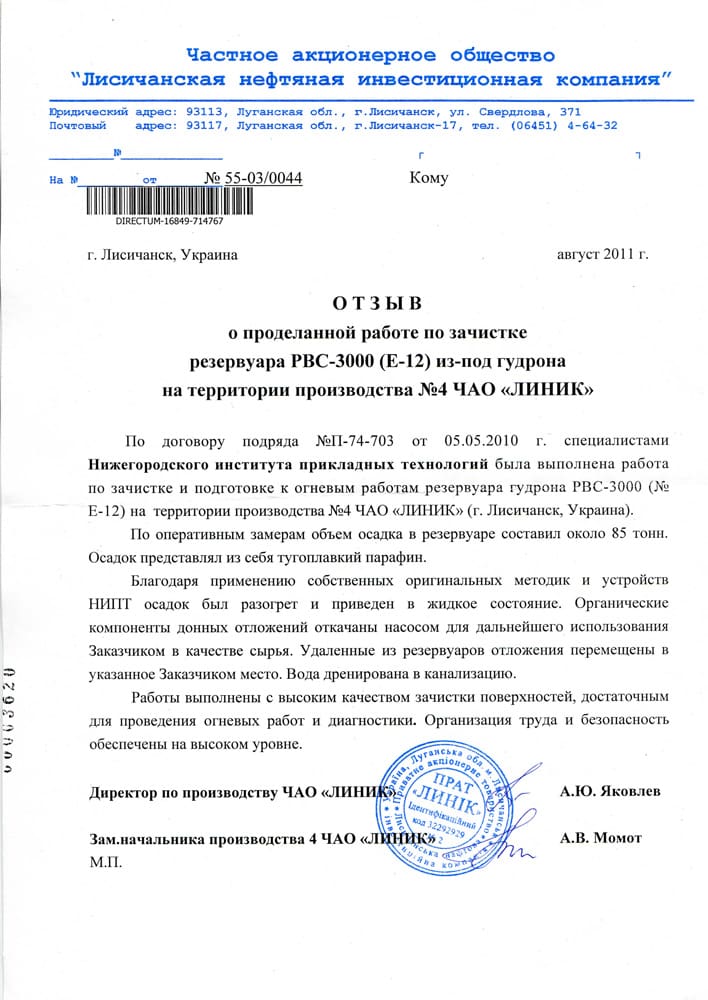

References

All petroleum derived organic residues were removed by pumps and used by the Client as feedstock in main production processes, and the whole scope of works was performed in accordance with high quality standards and within the agreed timeframe. The technology of tank solid sludge cleaning, developed and implemented by NNIAT LLC, is safe, cost effective, environmentally friendly, reduces work performance time, and can be recommended for wide use.

Organic part of the sludge was completely removed by pumps and disposed by transportation by the Client tank trucks. The whole scope of works was performed in accordance with high quality standards and within the agreed timeframe. The tank is prepared for hot works.

The whole scope of cleaning operations was performed in accordance with high quality standards and ahead of schedule. The tank solid sludge cleaning technology, developed and implemented by NNIAT LLC, can be recommended for wide application.

All petroleum derived organic residues were removed by pumps and used by the Client as feedstock, and the whole scope of works was performed in accordance with high quality standards and within the agreed timeframe.

The new technology of tank solid sludge cleaning, developed and implemented by NNIAT LLC, is safe, cost effective, environmentally friendly, reduces work performance time, and can be recommended for wide use.

Oil sludge tank cleaning technology, developed and applied by NNIAT LLC, is cost effective and safe.

Licenses and certificates

Request a quote for comprehensive tank maintenance

You can read more on the service page, or just contact us, and we will provide you with all the necessary information