Construction and erection of tanks of any capacity and complexity

- Site preparation and foundation construction

- Vertical and horizontal tanks

- Tanks and vessels for any Oil and Gas facility

- Tank farms, terminals, fire stations, oil storage facilities, oil depot, etc.

Request a quote for tank construction and erection

Certification

Installation works are performed in accordance with the "Certificate of admission to specific types of works that affect the safety of capital construction facilities, including highly dangerous and technically complex ones."

Three steps of tank installation

Includes the full fledged foundation for aboveground or underground steel vessel, for example, of horizontal installation, designed to bear the weight of the structure.

Technique is determined based on the vessel type, dimensions and design features. In the selection of tank erection method, we are governed by the current Russian Federation regulatory system:

Includes the simulation of future operating conditions — imposing loads on the tank shell to detect defects and deficiencies of the designed system prior to the first start.

Featuring all aspects of oil tanks erection

Tank erection technology is defined depending on the tank weight, volume, location and type. Today most industrial facilities use horizontal systems, although vertical tanks for oil products are more common for high pumping volumes. The first type includes 2 types of tanks — aboveground and underground options. Standard vessel capacity estimates to 100 m3 (less frequent — 200 m3).

Completion of installation works

Our experience

We have been executing challenging tank cleaning projects since 2008.

Tanks of all types and sizes at oil refineries, pumping stations, product and raw material bases, oil terminals, power plants and boiler houses, including damaged and emergency tanks, as well as tanks with damaged bottom, with flooded and dropped to the bottom pontoons.

References

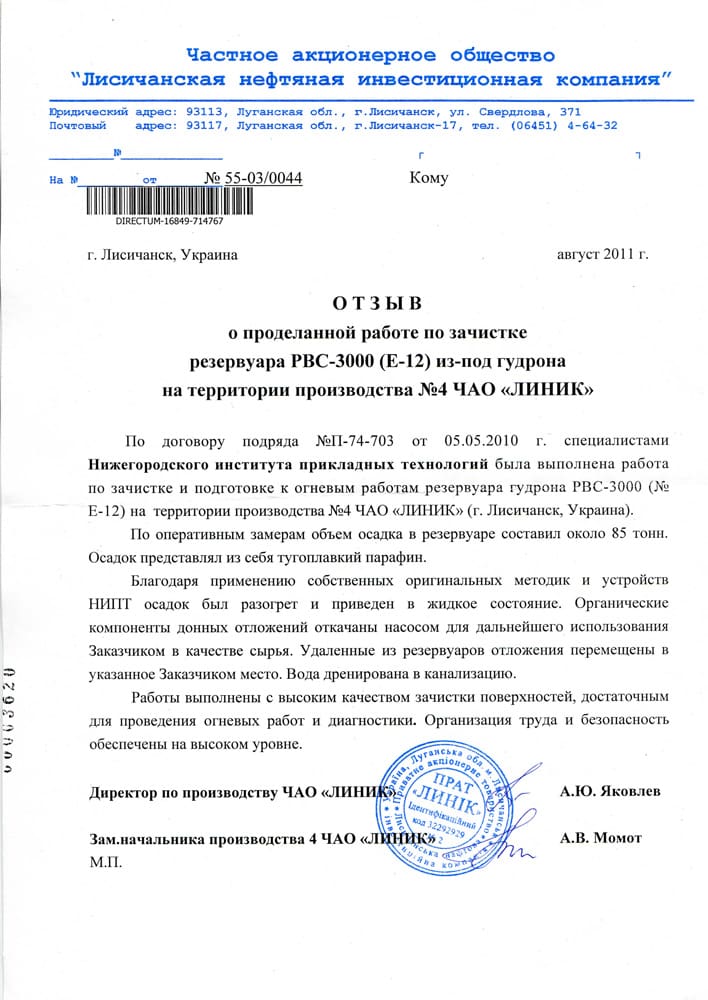

All petroleum derived organic residues were removed by pumps and used by the Client as feedstock in main production processes, and the whole scope of works was performed in accordance with high quality standards and within the agreed timeframe. The technology of tank solid sludge cleaning, developed and implemented by NNIAT LLC, is safe, cost effective, environmentally friendly, reduces work performance time, and can be recommended for wide use.

Organic part of the sludge was completely removed by pumps and disposed by transportation by the Client tank trucks. The whole scope of works was performed in accordance with high quality standards and within the agreed timeframe. The tank is prepared for hot works.

The whole scope of cleaning operations was performed in accordance with high quality standards and ahead of schedule. The tank solid sludge cleaning technology, developed and implemented by NNIAT LLC, can be recommended for wide application.

All petroleum derived organic residues were removed by pumps and used by the Client as feedstock, and the whole scope of works was performed in accordance with high quality standards and within the agreed timeframe.

The new technology of tank solid sludge cleaning, developed and implemented by NNIAT LLC, is safe, cost effective, environmentally friendly, reduces work performance time, and can be recommended for wide use.

Oil sludge tank cleaning technology, developed and applied by NNIAT LLC, is cost effective and safe.

Licenses and certificates

Guaranteed safety at the facility

Works at the facility are performed in compliance with safety requirements established by the Russian Federation laws, international standards, as well as safety requirements of the Client.

NNIAT LLC is licensed by RosTechNadzor (RTN) for the operation of industrial facilities with explosion, fire and chemical hazards of I, II and III class. Occupational health and Industrial safety Management system is in compliance with OHSAS 18001 requirements.

The personnel is duly qualified and certified, undergoes all the necessary types of trainings, briefings, internships and knowledge assessments. The personnel is fully equipped with personal and collective protective equipment, undergoes preliminary and regular medical examination.

Tank cleaning is carried out under a patented technology that minimizes the risks of incidents and accidents.

Request a quote for tank construction and erection

You can read more on the service page, or just contact us, and we will provide you with all the necessary information