Environmental solutions to treat and dispose of oily waste. NNIAT experience

NNIAT is one of the major oil service providers across the Russian Federation. Our company's primary advantages are implementation and compliance with the highest environmental standards, as well as the application of effective technologies aimed at conserving the environment and optimizing the Clients' business operations.

Since the range of environmental problems is quite broad, NNIAT specialists constantly face the need to develop engineering solutions for each specific case.

Experts in engineering and R&D can offer a wide range of high-performance technologies to eliminate the negative impacts of any contamination.

Environmental solutions to treat and dispose of oily waste.

One of the main NNIAT business lines is the treatment and disposal of oily waste.

NNIAT's technological and production capabilities enable it to handle both newly formed and obsolete oily waste.

As a rule, the production cycle comprises oil sludge pre-treatment, hydrocarbon recovery, and sediment disposal using a biological preparation. The oil sludge pre-treatment technique is identified based on laboratory testing results for the physical and chemical properties, as well as the water content of oil sludge.

After being treated at the unique centrifuges, the homogenized sludge separates into solids and liquids: cake and centrate. Hydrocarbons resulting from centrate settling are recovered and transferred to the Client, and the water is re-used. The cake is transported to the bioremediation site for further microbiological treatment. Depending on the waste amount, it is disposed of in one or several cycles.

For waste disposal, NNIAT has developed and has been producing the biopreparation-oil destructor "ARKOIL" which proved effective due to its high oil-oxidizing ability. The results of the laboratory chemical analyses of the biologically remediated soil fully comply with TU 5711-003-93754080-2014 for human-modified compostable soil mixture (technosol).

The soil has a certificate of conformity № ROSS RU.HB61.H20292. It can be used for road filling, leveling the terrain, and backfilling pits and ravines.

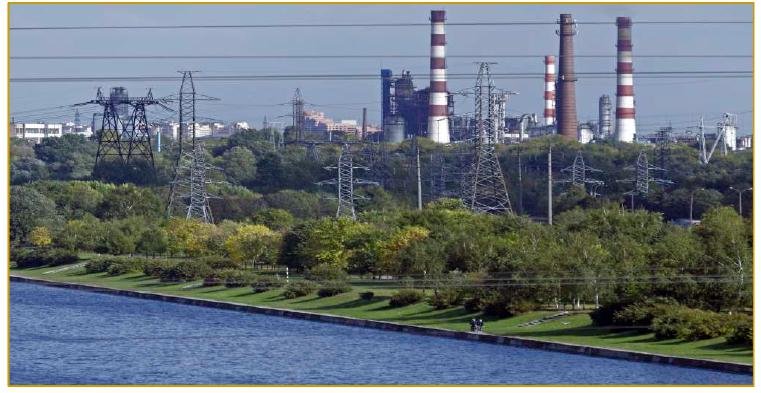

A number of projects will showcase the successful application of several technologies at one of the major Russian oil refineries.

32 treatment facilities with oil sludge were dismantled in 2013-2014 as a part of the project “Reduction of the negative environmental impact”. Also, more than 10 hectares of oil-contaminated soils were remediated.

This project is significant because the Nizhny Novgorod Institute of Applied Technologies performed the work on a turnkey basis, including:

- engineering survey;

- development of design and estimate documentation for dismantling;

- assessment of the amount of contaminant and degree of soil contamination;

- identification of the amount, hazard class of waste, and suitable disposal methods;

- dismantling of hydraulic structures

- development of soil remediation plan after dismantling of the facilities.

150,000 m3 of oily waste was treated. Centrifuges enabled us to dispose of waste using a closed-loop technology with further hydrocarbons recovery.

Around 600,000 m3 of oil-contaminated soil was flushed and remediated (without excavation).

Advantages of the technology:

- end-to-end solution to the oily waste accumulation problem;

- hydrocarbons recovery;

- elimination of negative environmental impacts;

- compliance of the technology with all environmental standards;

- individual selection of the best method of treatment, depending on qualitative parameters of oil sludge;

- high speed and efficiency of works performed thanks to equipment mobility;

- no weather and climate restrictions.

NNIAT’s 16-year experience in figures:

- over 3,000,000 m3 of oil-contaminated soil remediated;

- over 500,000 m3 of oily waste treated using closed-loop technology;

- over 550,000 m3 of oily waste treated using a microbiological method;

- over 80,000 tons of oil-containing fluid recovered from under the ground and returned to the Client.

Уважаемые коллеги и добрые друзья! Поздравляем вас с профессиональным праздником …

View all